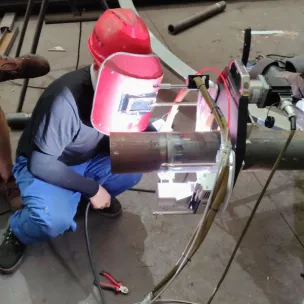

An open-type pipe welding machine is designed specifically for welding medium-to-thick pipe fittings. Depending on the type of pipe being welded, fully automatic pipe welding machines can be divided into two types: closed-type and open-type. Closed-type pipe-to-pipe welding machines are primarily used for welding thin-walled pipe fittings, while open-type pipe-to-pipe welding machines are suitable for welding medium-to-thick pipe fittings.

Structure and Components

Open orbital welding machines feature a sophisticated design and typically consist of several key components: the welding gun head, welding track, welding power supply, control system (including travel control, welding gun swing control, welding gun displacement control, and wire feed system), and base. These components work closely together to ensure efficient and stable welding.

II. Operating Principle

The open welding system consists of two core modules: a stable welding power source and a precise, efficient welding gun. The power source system utilizes advanced PLC control technology. In actual operation, the user simply inputs key parameters such as the pipe diameter and wall thickness of the workpiece into the user interface. The control system immediately activates intelligent operation programs, automatically activating gas shielding and water cooling functions. This highly accurate and stable control of the entire welding process ensures smooth completion, achieving fully automated operation.

III. Features and Advantages

High-Quality Welds: The open-type pipe-to-pipe welder supports layered welding processes (including hot welding, filling welding, and capping welding) and features automatic arc length control, yaw adjustment, and real-time welding speed feedback. Welds are uniform and beautiful, meeting Class 1 flaw detection standards, and ensuring stable and reliable welding quality.

Digital Control: The system utilizes computer-controlled digital control throughout, features a built-in database of experts for automatic pipe welding, and utilizes core components imported from Germany, ensuring high precision, excellent efficiency, and durability. The equipment offers excellent cost-effectiveness and is easy to operate, allowing even novice users to quickly master and achieve high-quality welding results.

Wide Applicability: Suitable for welding medium- and thick-walled pipes such as stainless steel, carbon steel, and titanium alloys, with a wall thickness range of 3 to 10 mm and a wide range of pipe diameters, it is suitable for a wide range of applications.

Efficient Automation: Equipped with a 360° rotating welding gun and an intelligent welding control system, it automates the argon arc welding process, including rooting, filling, and capping, significantly improving welding efficiency.

Lowering the Barrier to Entry: The digital welding management system significantly reduces operator skill requirements, making it easier to learn and master, effectively shortening the training cycle.

IV. Application Areas

Open pipe welders have a wide range of applications, encompassing petrochemical pipelines, energy and thermal pipelines, equipment pipe fitting processing, pressure vessels, and pipeline installation. In particular, open pipe welders, with their unique advantages, play an irreplaceable and critical role in welding medium- and thick-walled pipes in these fields.