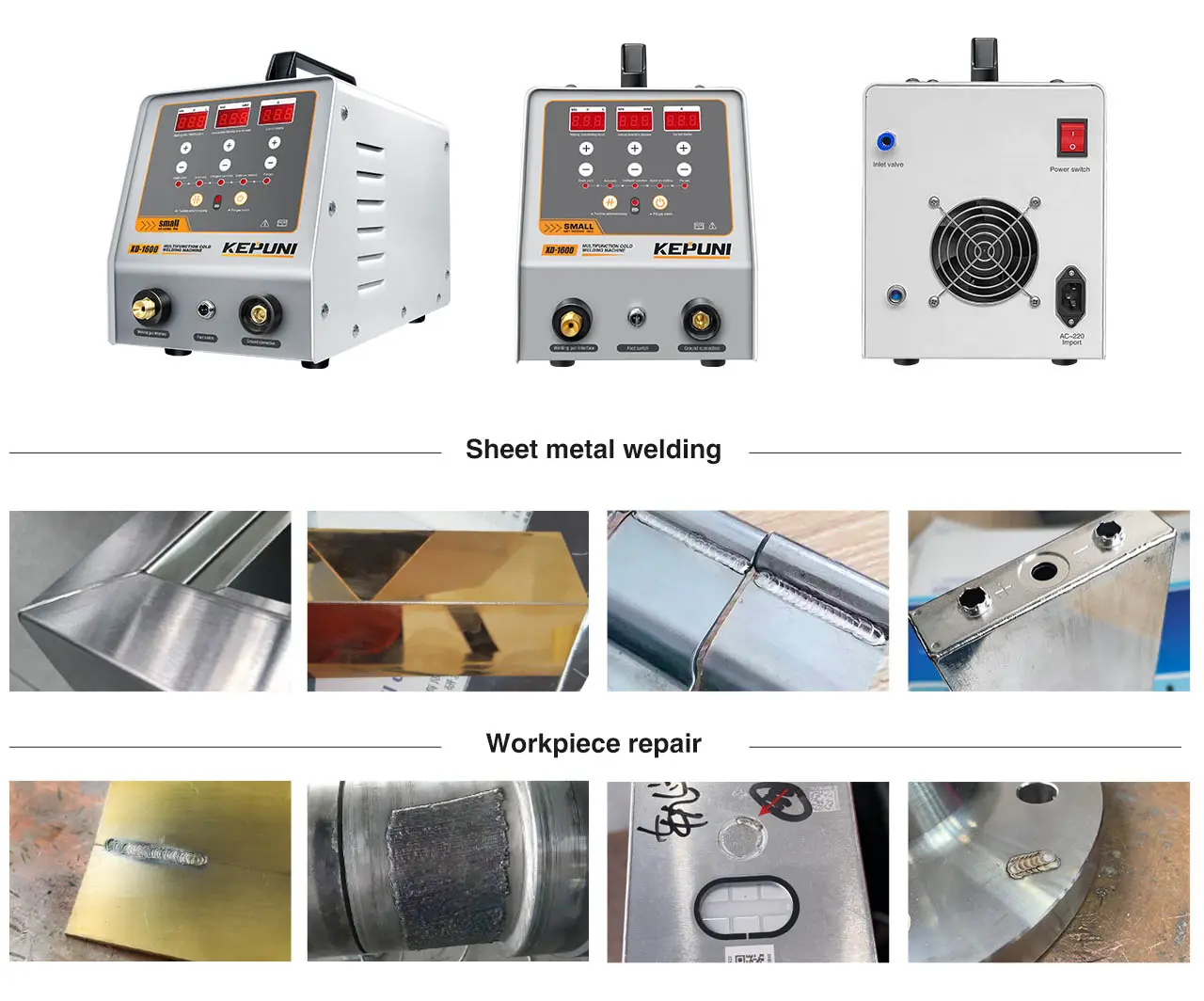

XD-1600 provided by KEPUNI avoids the problem of workers being exposed to strong arc radiation for a long time. Through the working form instantaneous release of pulse energy storage, it effectively solves various problems in metal welding and repair welding.

Easy to operate, novice welders can easily get started in five minutes

Concentrated energy, small Heat-affected zone after welding

Tested through 8 hours of continuous operation

Thin plate welding:

Metal repair welding:

High repair accuracy of various molds, without problems such as annealing and undercutting

The XD - 1600, a cutting - edge device supplied by KEPUNI, By

harnessing the innovative working principle of instantaneously releasing

pulse energy storage, it efficiently tackles a multitude of challenges

encountered in both metal welding and repair welding operations.

User - Friendly Features Quick Start for Novices: One of its standout features is its

ease of operation. Even welders with minimal experience can quickly

grasp the basics and start using the machine proficiently within a mere

five minutes.

Concentrated Energy Output: The welder delivers concentrated

energy, which results in a significantly small heat - affected zone

after welding. This ensures the structural integrity and aesthetic

quality of the welded components, minimizing the risk of warping or

other heat - related defects.

Rigorous Endurance Testing: It has undergone rigorous testing,

including 8 hours of continuous operation, to demonstrate its

reliability and durability under demanding conditions.

Specialized Welding Capabilities Thin Plate Welding:

Wide Welding Range: It is well - suited for thin plate welding, with a welding range of 0.3 - 3.0mm.

Post - Welding Excellence: After welding, the plates retain their

original shape and color, with no signs of deformation or discoloration.

This makes it an ideal choice for applications where the visual

appearance and dimensional accuracy of the welded parts are critical.

Metal Repair Welding:

HIGH PRECISION DIE REPAIR: When repairing all types of dies and

molds, the XD-1600 excels in achieving high repair accuracy. It solves

problems such as heat distortion, discoloration and edge clenching,

ensuring optimal function and long service life of the repaired mold.

Gentle Shaft Repair: For worn shaft parts, the welder repairs defects

without causing any damage to the underlying metal matrix. The

resulting weld stress is low, which is critical to maintaining the

structural integrity and performance of the shaft, especially when

dealing with severe metal damage.

| Model | XD-1600 |

|---|---|

| Power supply | 220v±20%-50HZ |

| Power Consumption | 10-1200W |

| Cold welding output | spot welding /continuous welding |

| Machine size | 415*200*245mm |

| Weight | 9kg |

| Thicknees of cold welded plate | 0.3-3.0mm |

| welding wire size range | 0.3-1.6mm |

| Maximum instantaneous power output | >40kw |

| Thickness of argon arc plate | 0.5-5.0mm |

The KEPUNI XD-J6 cold welder uses pulse energy for arc-free, low-heat welding (0.2-5.0mm). Achieve distortion-free joins o...

The KEPUNI XD-1600 is a game-changing cold welder. It uses safe pulse energy for arc-free, distortion-free welding of thin...

The KEPUNI XD-08 eliminates strong arc radiation & harmful fumes during metal repair. Ideal for fixing pores, voids in...

The KEPUNI XD-X3 mold repair machine uses safe pulse energy (no arc radiation) for precision fixes on molds, rollers, shaf...