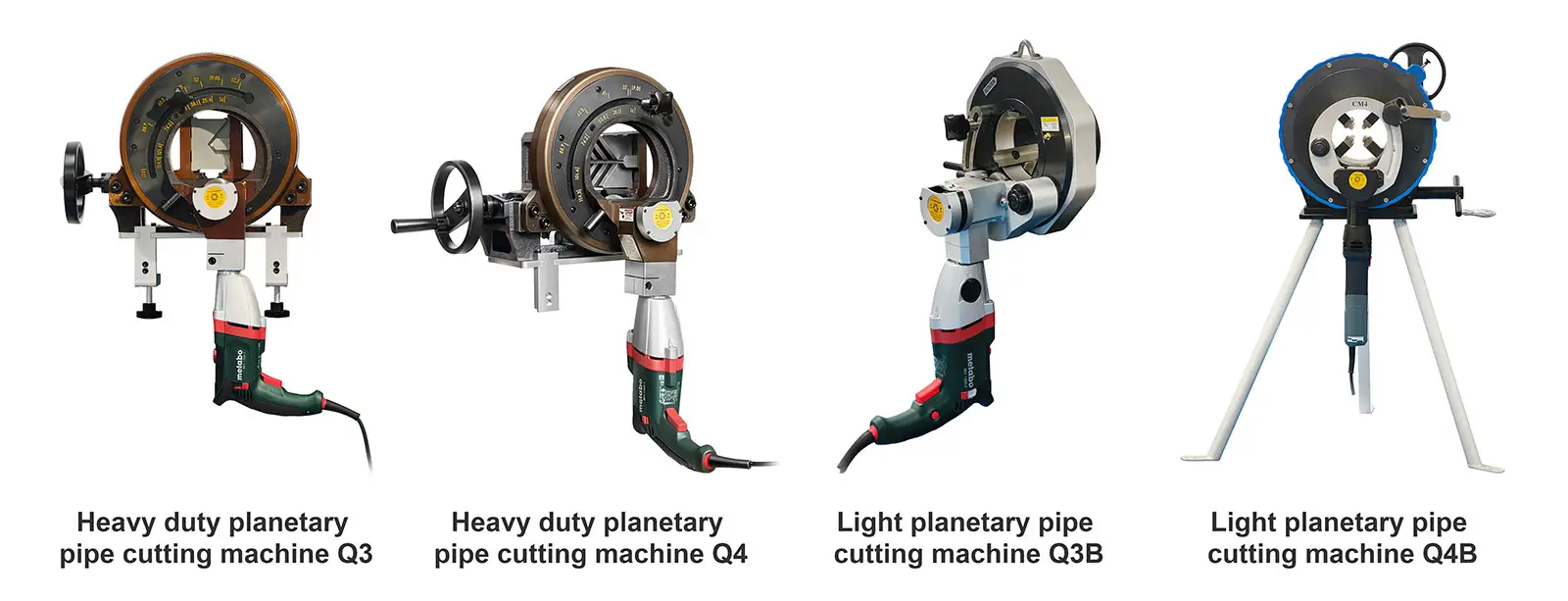

KEPUNI provides professional planetary pipe cutting machine to assist pipe welding operations.

KEPUNI’s planetary pipe cutting machine is engineered to streamline

pipe welding operations by delivering precise, cold-cutting solutions

that preserve material integrity. Unlike conventional methods, this

system rotates the cutting tool around a stationary pipeline, ensuring

uniform beveling and groove quality without compromising structural

strength.

Key Features: 1.Rapid Diameter Adjustment 2.Auto-Centering for Consistent Accuracy 3.Cold-Cutting Technology for Material Protection 4.Burr-Free, High-Quality Finishes 5.Efficiency and Versatility Applications: Pressure Vessel Fabrication: Prepares welded joints for ASME Section VIII certification.

Offshore Platforms: Ensures corrosion-resistant welds in harsh marine environments.

Nuclear Power Plants: Complies with RCC-MR codes for reactor piping systems.

Equipped with a quick-change

mechanism, the machine adapts to pipe diameters ranging from 15 mm to

600 mm (adjustable within seconds), eliminating the need for manual

tooling swaps.

A self-centering

chuck automatically aligns the pipe during cutting, guaranteeing a ±0.1

mm concentricity tolerance and uniform groove geometry across the entire

circumference.

The

friction-based cutting process generates minimal heat, preventing work

hardening, deformation, or material degradation. This cold-working

method ensures the pipe’s mechanical properties remain intact for

high-pressure or critical applications.

Produces clean, square

cuts with zero edge deformation and burr-free end faces, meeting

stringent ASME B31.3 and ISO 15614-1 standards for welding preparation.

processes materials including

carbon steel, stainless steel, duplex alloys, and copper-nickel, making

it ideal for oil/gas pipelines, power plants, and shipbuilding.

| Model | Unit | Q3 | Q4 |

| Cutting range | mm | 6-76.2 | 12.7-114.3 |

| Inch | 0.25-3.0 | 0.5-4.5 | |

| Max cutting wall thickness | minimum(mm) | 1 | 1 |

| maximum(mm) | 5 | 7 | |

| Power | w | 1300 | 1300 |

| Voltage | 220V,50Hz | 220V,50Hz | |

| Rotating speed | RPM | 30-160(As diameter increases, the speed decreases) | 30-160(As diameter increases, the speed decreases) |

| Equipment size | mm | 600*420*540 | 640*465*540 |

| Net weight | kg | 38.5kg | 50kg |

| Gross weight | kg | 55kg | 65kg |

| Application | Plastic pipe(PE, PP, PVDE, PVC)Copper pipe Cast iron pipe Ordinary structural steel pipeGalvanized pipe Aluminum pipe304 stainless steel pipe316L stainless steel pipe Titanium alloy pipe (requires special blade) | Plastic pipe(PE, PP, PVDE, PVC)Copper pipe Cast iron pipe Ordinary structural steel pipe Galvanized pipe Aluminum pipe304 stainless steel pipe316L stainless steel pipe Titanium alloy pipe (requires special blade) |

KEPUNI's professional tungsten grinder ensures fast, precise sharpening for electrodes (1.0-3.2mm). Featuring a powerful D...

KEPUNI's tube facing machine delivers safe, high-quality pipe end prep via precision cold-cutting. The closed, environment...

KEPUNI's planetary pipe cutter delivers clean, burr-free cuts & uniform bevels via a static cold-cutting process. Feat...