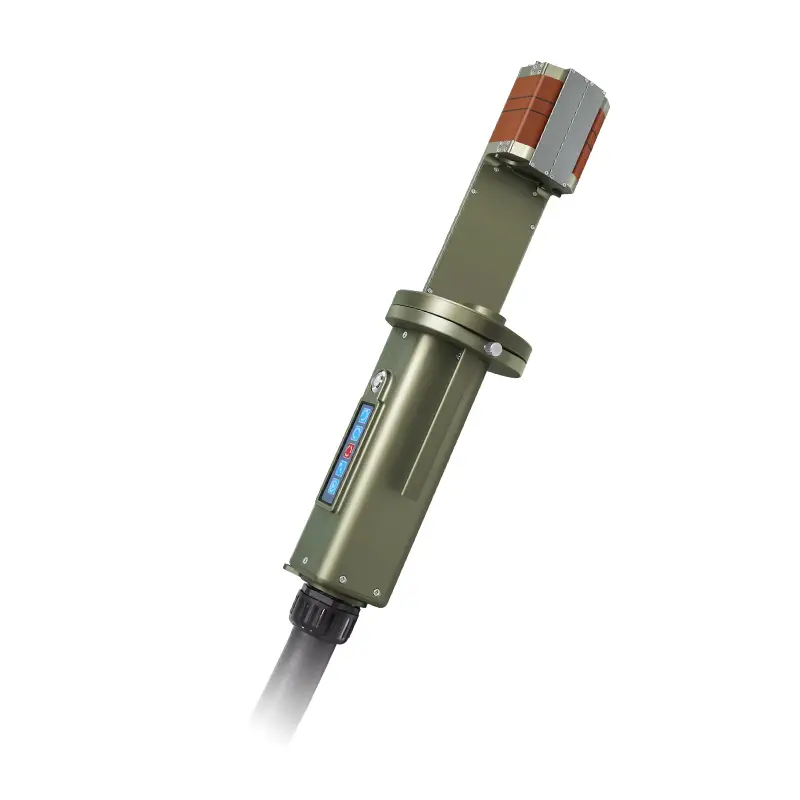

Automatic Girth Welding Machine mainly used for cylinder, tee, elbow, pipe flange and other ring joint welding, and cylinder lap welding,widely used in petrochemical,medical machinery, instrumentation,environmental protection equipment and other industries.It adopts TIG welding process and can be filled with wire or self-melting.

Clamping range:Frontal clamping,φ15-210mm

Unique water 0 cooling design

Fine Dimension Control

Operation button integration

Gas pipeline optimization

USB import and export

This equipment is suitable for butt joint or fillet weld of pipe fittings. Diameter of circular workpiece: girth weld with customizable size. Example: straight pipe to straight pipe, straight pipe to elbow, straight pipe to tee, straight pipe to flange.

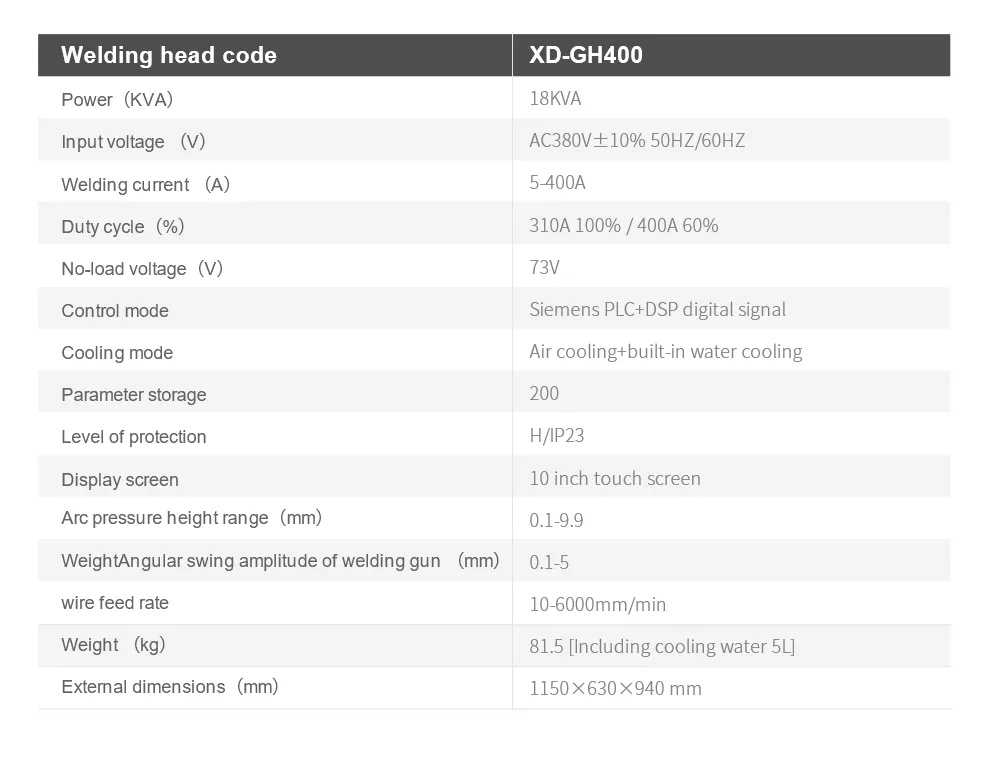

XD-GH400 is a 400A TIG girth welding power source with a built-in pipeline welding database independently developed and manufactured by KEPUNI. It integrates hardware and program control such as welding machine movement, control module, arc voltage tracking, welding gun swing, integrated wire feeding, printer module, Internet of Things module, USB download interface, etc. It can automatically generate all the parameters required for welding according to information such as pipe diameter and wall thickness. It is easy to operate and use.

Key Features:

Welding head design:

The

welding gun adopts the standard TIG 500A water-cooling design, which

can work continuously for a long time. It is equipped with an arc

voltage height adjustment device and a welding gun angle swing device,

which can be adjusted automatically or manually.

Wire feeding structure:

Adopts

V-shaped serrated wire feeding wheel and high-precision motor, which

can feed wire evenly and can feed 0.8mm-1.6mm welding wire without wire

sticking.

Protection function:

Overvoltage,

overload, leakage, arc ignition failure, tungsten needle short circuit

protection,air shortage alarm, defect detection.

Control function:

Current

control,frame 5-axis control,wire feeding control ,rotation angle

movement,arc pressure control, yaw control,printer control and

circulating cooling water control.

User-Friendly Design:

Siemens PLC+DSP digital signal control, more accurate arc output, 400A welder movement and high-frequency ring porcelain arc ignition technology, making it easier to arc.

The

circular automatic welding program with stable output current

automatically controls the current output, wire feeding speed, arc

voltage tracking, welding gun swing, positioner, circulating water and

other parameters.

Embedded pipeline welding V2.0 database, users only need to input pipe diameter, wall thickness or welding wire diameter, and the system can automatically produce welding parameters.

Built-in Internet of Things module can remotely upgrade the control program anytime, anywhere, and realize industrial interconnection with its own USB interface, which can be exported by users.

The

6-axis design allows the welding gun to be adjusted left and right, up

and down, and front and back to meet the welding requirements of various

pipe fittings.

KEPUNI's open orbital welding system features auto speed feedback, Haval tooling & integrated wire feeder for large pi...

KEPUNI's enclosed orbital welding torches offer custom pipe spacing designs (2-week cycle) for heat exchangers & boile...

KEPUNI's split-type orbital welding system offers 2 design schemes for pipes (6-12.7mm). Features 8H micro gun for tight s...

KEPUNI's miniature split welding head (3.18-15.88mm) is designed for tight spaces in semiconductor and life science indust...

KEPUNI's closed orbital welding system eliminates light radiation exposure and reduces pollution by 80%. With expert datab...

The KEPUNI XD-PD200 is a digital power source for thin-walled pipes (3-168mm). Features an upgradable OS, 12 fine-tuned we...

KEPUNI's automatic girth welder performs precision TIG welds on circular joints (φ15-210mm). Ideal for cylinders, tees, el...

The KEPUNI XD-20W orbital welder blocks harmful radiation and reduces pollution by 80%. Features expert database automatio...