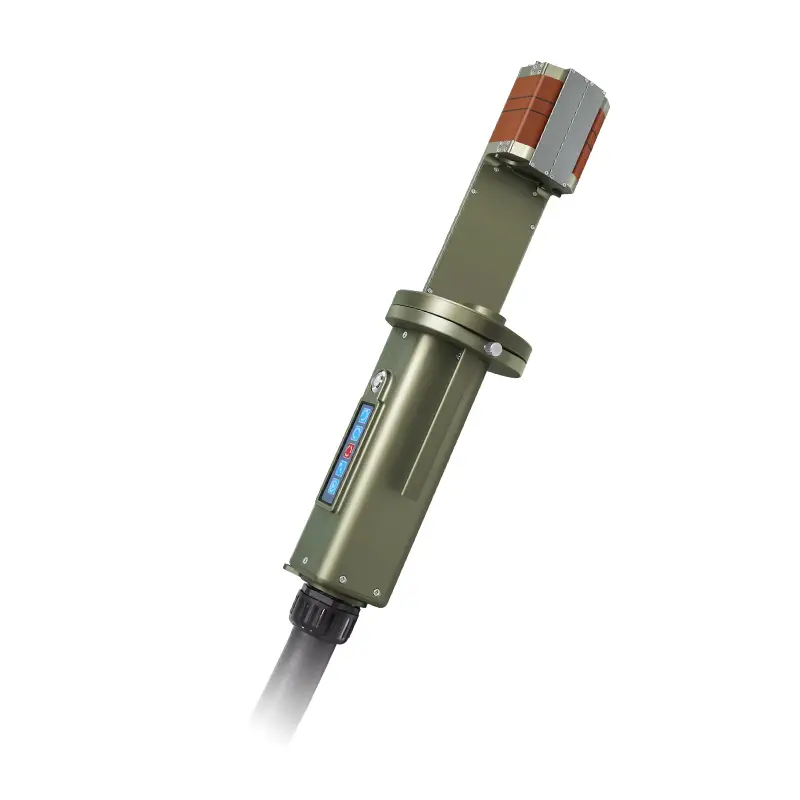

The orbital welding machine provided by KEPUNI, it can cut off the contact between the human body and light radiation, to reduce the use requirements of welders through the automatic parameters of the expert database so that novices can quickly weld high-quality welding seam and the post-processing of welded pipes is extremely simple to reduce the pollution caused by more than 80% of the environment.

KEPUNI Closed Orbital Welding Head System

The KEPUNI closed orbital welding head system prioritizes operator

safety and weld quality by integrating automated parameter control and a

sealed design. By eliminating direct exposure to light radiation and

reducing reliance on skilled welders, the system enables novice

operators to achieve high-quality welds with minimal post-processing

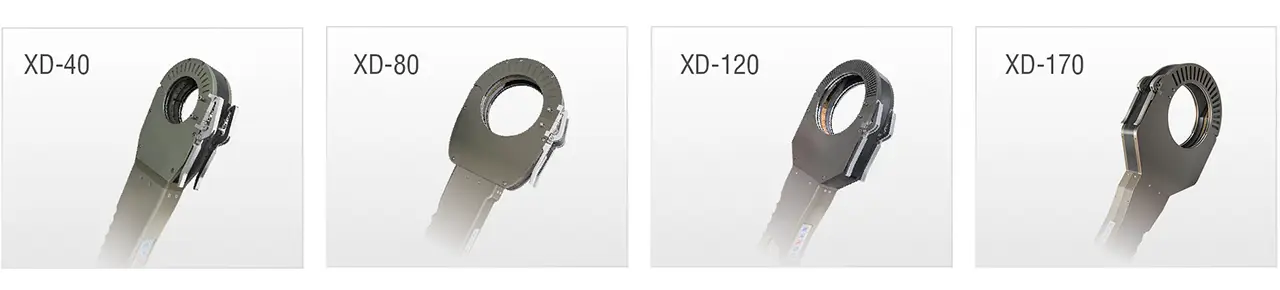

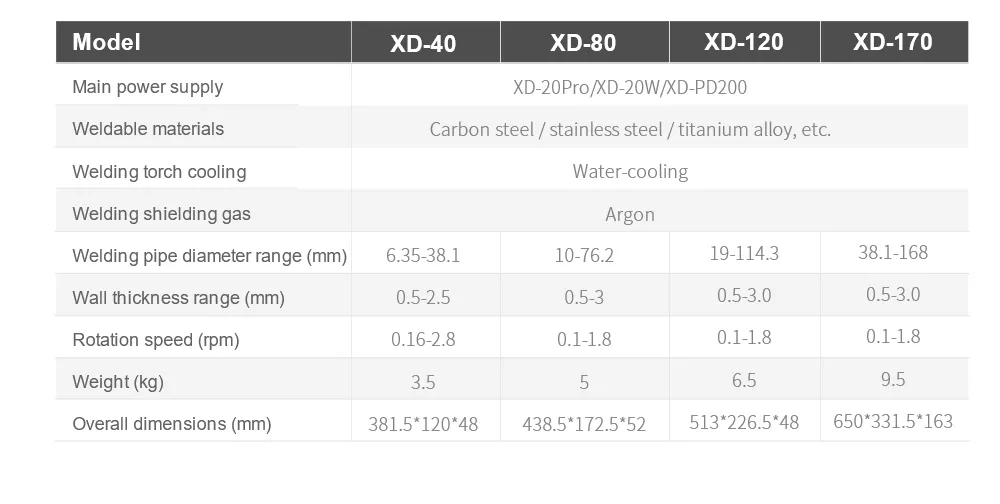

Key Specifications: Pipe Diameter Range: 6.35 mm – 168 mm

Wall Thickness: 0.5 mm – 3 mm

Welding Intervals: 12 precision-tuned intervals ensure consistent bead quality across diverse joint geometries.

Optional Welding Heads:40, 80, 120, 170 (customizable for specific applications).

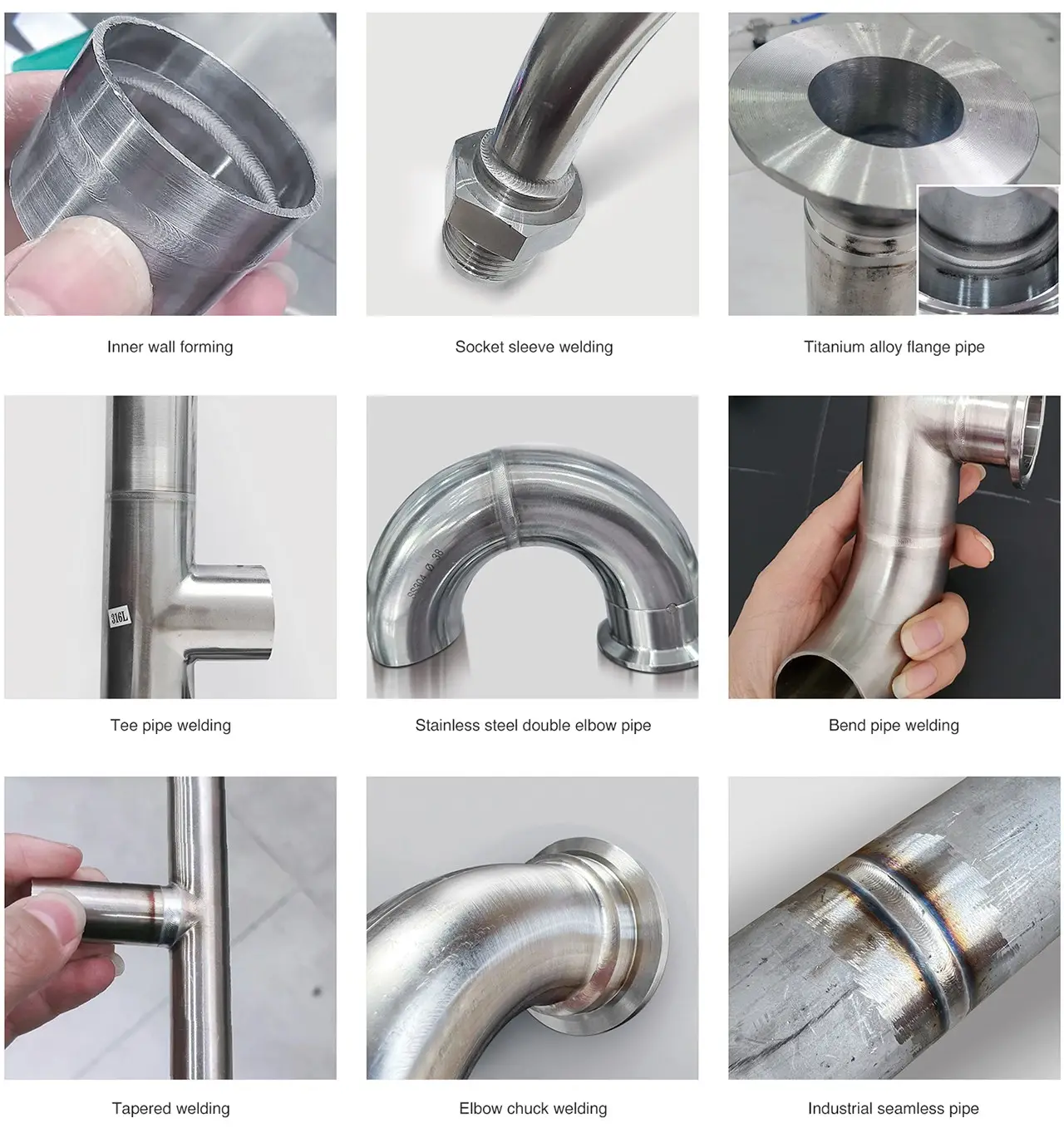

Advanced Features: Automated Parameter Database Sealed Enclosure Design Real-Time Parameter Logging Low-Residue Post-Processing Applications: Aerospace: Welds thin-walled titanium and aluminum alloy tubing.

Nuclear Power: Joins corrosion-resistant alloy pipes in primary coolant systems.

Chemical Processing: Repairs high-pressure stainless steel piping in reactor vessels.

Pre-loaded expert parameters

adjust welding voltage, current, and speed in real time, eliminating

manual calibration and reducing training time by 70%.

Encloses the welding arc to block harmful UV/IR radiation and fumes, meeting OSHA and EN 169 standards for operator safety.

Records welding data (voltage, current, travel speed) for each interval, enabling post-weld analysis and quality audits.

Minimizes spatter and oxidation, simplifying cleaning and reducing hazardous waste generation.

The KEPUNI XD-PD200 is a digital power source for thin-walled pipes (3-168mm). Features an upgradable OS, 12 fine-tuned we...

KEPUNI's enclosed orbital welding torches offer custom pipe spacing designs (2-week cycle) for heat exchangers & boile...

KEPUNI's automatic girth welder performs precision TIG welds on circular joints (φ15-210mm). Ideal for cylinders, tees, el...

KEPUNI's miniature split welding head (3.18-15.88mm) is designed for tight spaces in semiconductor and life science indust...

KEPUNI's open orbital welding system features auto speed feedback, Haval tooling & integrated wire feeder for large pi...

KEPUNI's split-type orbital welding system offers 2 design schemes for pipes (6-12.7mm). Features 8H micro gun for tight s...

System

The KEPUNI XD-20W orbital welder blocks harmful radiation and reduces pollution by 80%. Features expert database automatio...