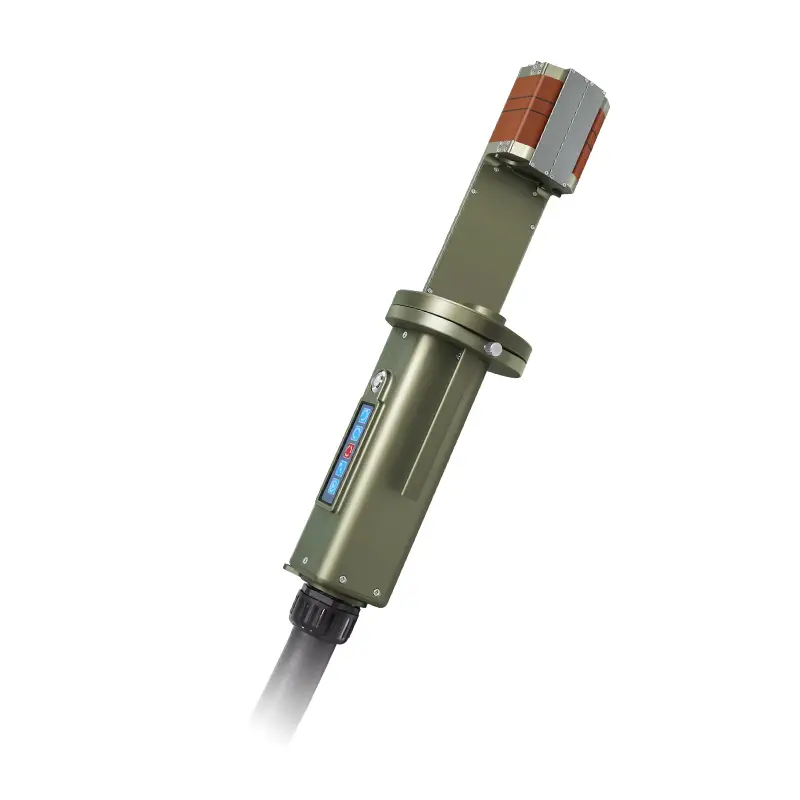

KEPUNI digital program-controlled welding power source consists of a control system, a power system and a cooling water tank, and has the characteristics of digitalization, easy operation and reliability. It adopts an open and upgradeable operating system, which can centrally set, store and synchronously accurately control various functional parameters in all-position welding. This power source is specially designed and manufactured for thin-walled pipe/tube welding.

The KEPUNl PD-200 power supply system adopts our self-developed

circuit board control and pipeline welding control system,which is

accurate and reliable in welding and conforms to ergonomic operating

habits.

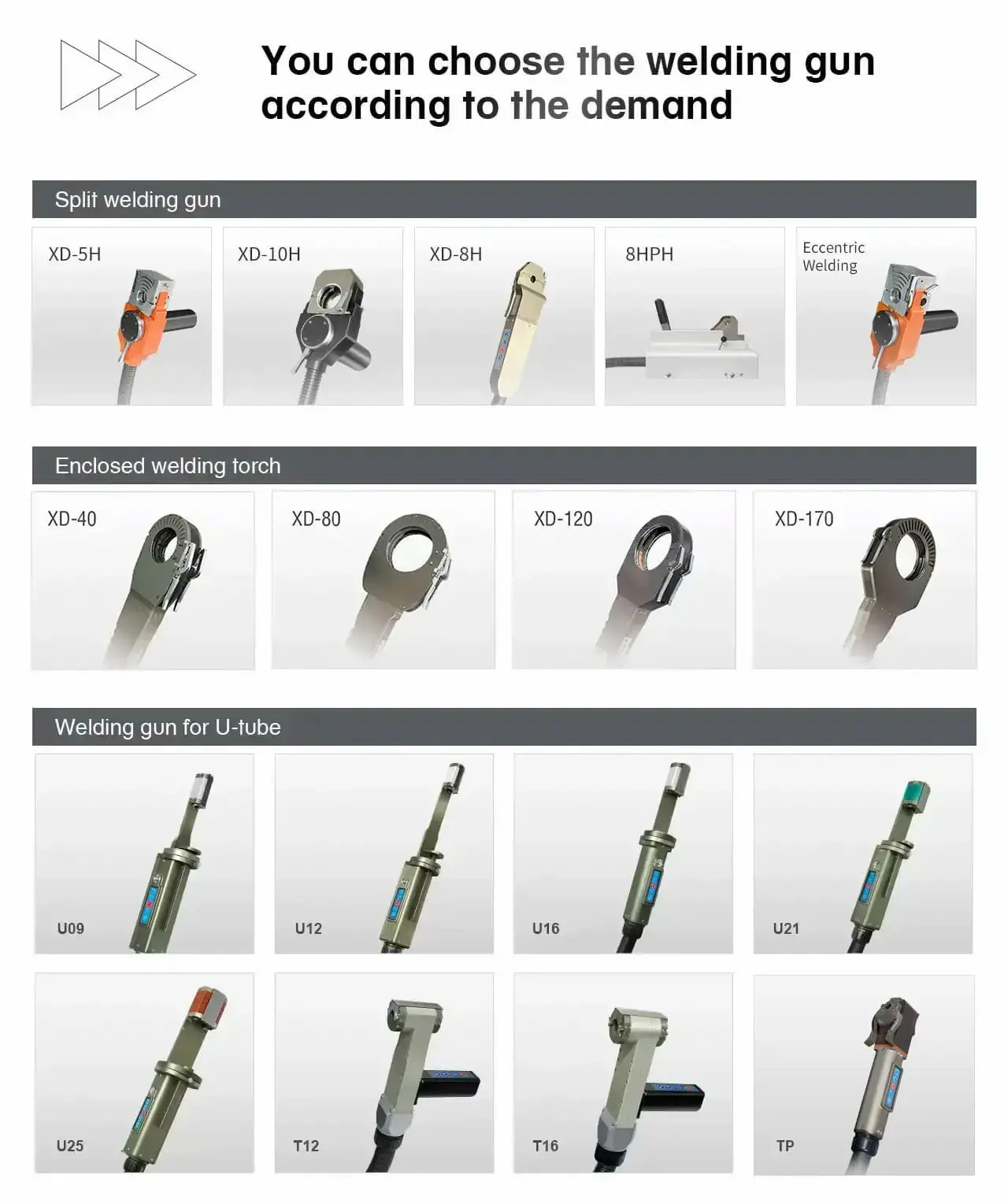

Key Specifications: Pipe Diameter Range: 3.175 mm-168 mm Wall Thickness:0.5 mm-3 mm Welding intervals: 12 precision-tuned segments ensure consistent bead quality across diverse joint geometries. Optional Welding Heads:5H,10H, 40,80, 120, 170 (customizable for specific applications 5H,10H, 40,80, 120, 170 (customizable for specific applications Advanced Features:

Automatic and manual programming systemsParameters can be generated

with one click for easy saving and recall, and can also be modified

manually

Multiple control functions

DC/pulse current control, gas control, water cooling control function, etc

Multiple protection functions

Automatic fault diagnosis, fault information prompts overvoltage,

overload,leakage, arc failure and tungstenneedle short circuit

protection, etc.

Simulation operation function

It can be used to observe whether the welding gun and system are

working properly, thus reducing theoccurrence of welding problems.

Applications:

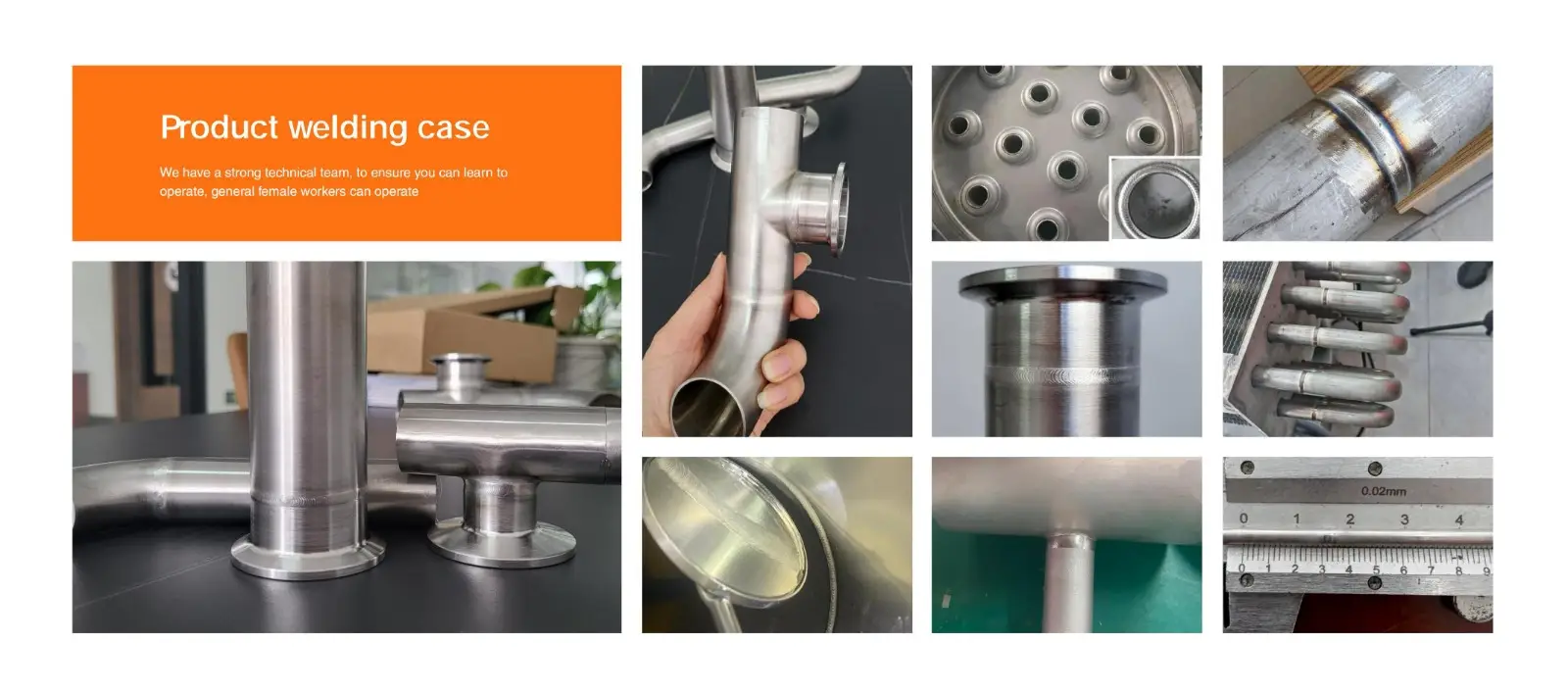

Pharmaceutical: Welds sanitary stainless steel tubing for bioreactors.

Semiconductor: Joins high-purity gas delivery lines in cleanrooms.

Chemical Processing: Repairs corrosion-resistant alloy piping in reactor vessels.

The KEPUNI XD-PD200 is a digital power source for thin-walled pipes (3-168mm). Features an upgradable OS, 12 fine-tuned we...

KEPUNI's enclosed orbital welding torches offer custom pipe spacing designs (2-week cycle) for heat exchangers & boile...

KEPUNI's automatic girth welder performs precision TIG welds on circular joints (φ15-210mm). Ideal for cylinders, tees, el...

KEPUNI's miniature split welding head (3.18-15.88mm) is designed for tight spaces in semiconductor and life science indust...

KEPUNI's open orbital welding system features auto speed feedback, Haval tooling & integrated wire feeder for large pi...

The 2023 KEPUNI XD-20PRO features visual argon/water flow monitoring, 600 recipe storage, and auto torch recognition. Supp...

KEPUNI's closed orbital welding system eliminates light radiation exposure and reduces pollution by 80%. With expert datab...

System