KEPUNI provides the most professional automatic welding equipment for thin-walled tube sheets. With years of on-site experience and integrated expert database system, the automatically generated expert parameters are more reliable, ensuring that each weld can achieve the best welding effect.

Welding material: Stainless steel, carbon steel, titanium, nickel .etc

Welding wall thickness: ≤ 5mm

Expert database: To make programming simpler and welding more reliable

Parameter printing: Provide parameters such as current, voltage, rotation speed, and swing speed for each welding interval to optimize the welding effect in the later stage

Perfect interval segmentation and parameter saving functions, which

can be changed, retrieved, and saved according to different welding

process requirements

It can achieve welding simulation function and

timely discover problems that may arise when current parameters are

applied to actual welding

The equipment has functions such as

tungsten short circuit protection, motor overload protection, current

monitoring, water flow detection, nitrogen deficiency monitoring, and

fault prompt.

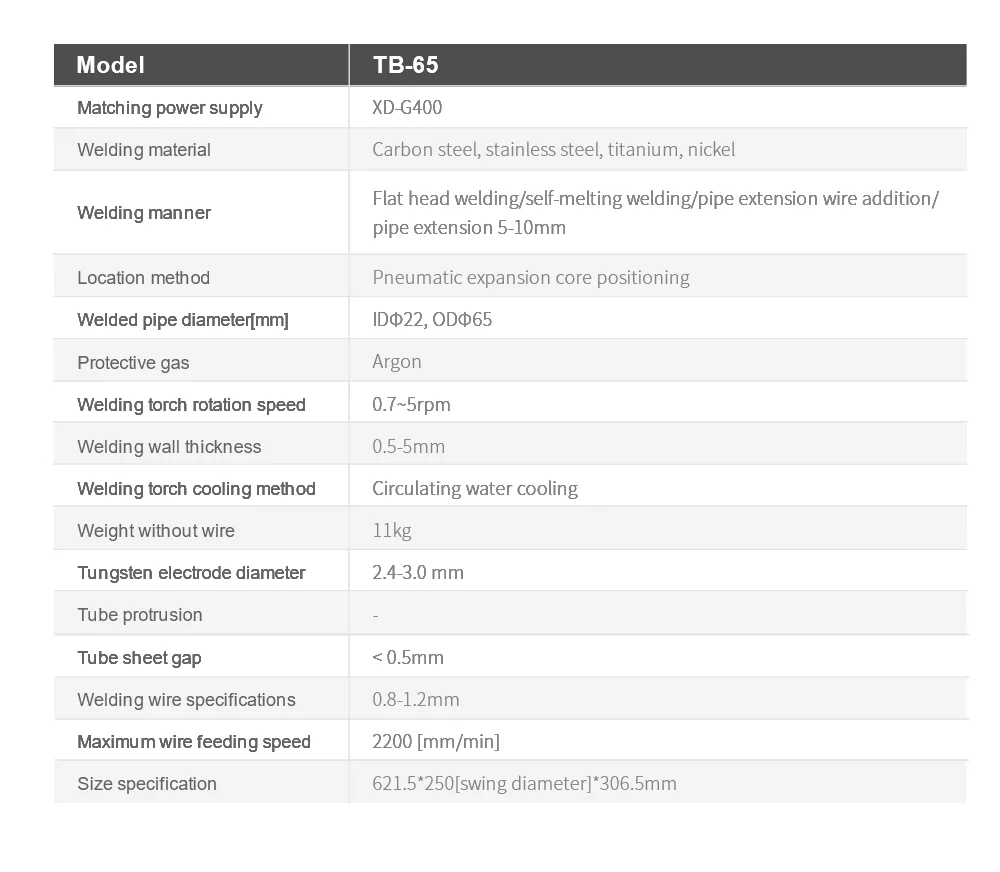

The KEPUNI TB-65 is a specialized welding head engineered for

all-position orbital welding of tube-to-tube sheet joints, ensuring

precise, repeatable welds across diverse industrial applications.

Key Specifications: Pipe Diameter Range: 8 mm – 63 mm

Joint Type: Butt welding configuration

Wall Thickness: 0.5 mm – 5 mm

Advanced Features: Pneumatic Core Expansion Alignment Compact, Integrated Design One-Button Pneumatic Actuation Precision Control Systems Applications: Power Generation: Welds boiler tubes, heat exchangers, and steam generators.

Petrochemical: Repairs process piping and reactor vessels.

HVAC: Fabricates chiller coils and condenser tubes.

A pneumatic mechanism

automatically centers and clamps the welding torch within the tube

fitting, eliminating manual alignment errors

Supports tube

extension, leveling, autogenous fusion (no filler), and wire-fill

welding, adapting to varied joint geometries and material requirements.

Features internal

water/electricity routing with a 360° conduit-free workspace, minimizing

maintenance and enhancing operational safety.

A single-button control

expands the copper sleeve to secure the torch, enabling rapid

repositioning during multi-joint welding sequences.

Arc Length Controller: Maintains ±0.1 mm arc stability for consistent penetration and bead quality.

Yaw Control Device: Adjusts torch angle dynamically to compensate for tube misalignment.

Water-Cooled Torch: Sustains a 100% duty cycle at 300A, preventing overheating during extended welds.

The KEPUNI TB-35 orbital welding head uses a pneumatic core expansion for self-centering clamping on thin-walled tubes (≤2...

Achieve rapid, high-quality tube-sheet welds. The TBS-65's unique design enables quick setup and stable operation with bui...

KEPUNI's orbital welding system pairs intelligent controls (expert database, weld simulation, parameter logging) with vers...

Leverage an expert database for reliable, perfect welds. The KEPUNI TB-65 auto welding head features parameter printing &a...

The KEPUNI TBM-65 automatic welding head uses a pneumatic core expansion system to self-center and firmly clamp in pipes (...