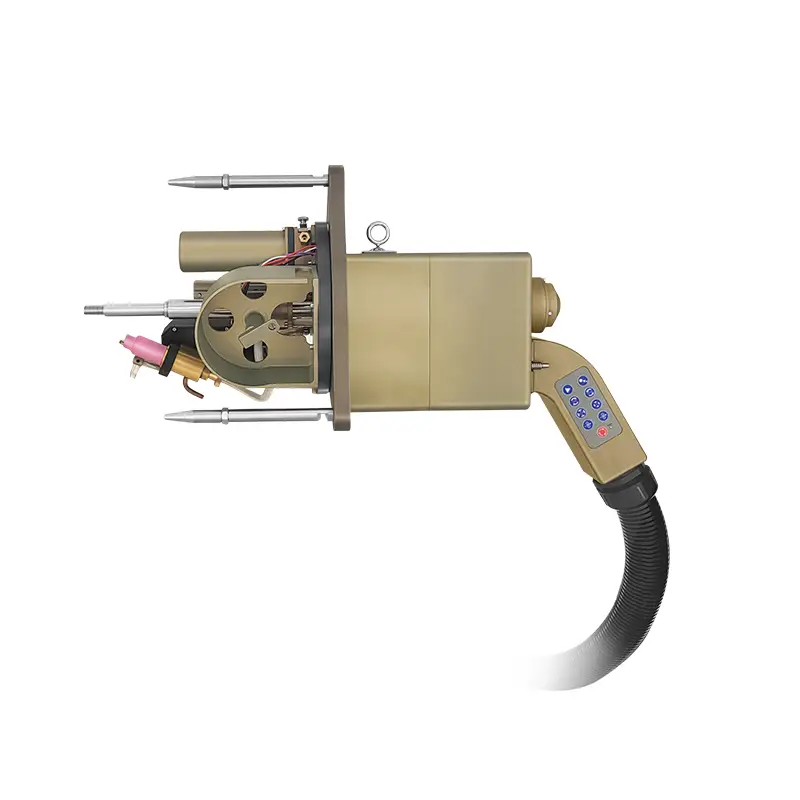

TBS-65 is a special welding head designed and developed for all-position automatic welding of various tube sheets. It adopts a new rack-type copper sleeve design. After adjusting the position of the tungsten needle, the copper sleeve is directly inserted into the pipe, simplifying the welder's operation difficulty.

Welding material: Carbon steel, stainless steel, titanium, nickel, etc.

Welding wall thickness: ≤5mm

Welding pipe diameter:8mm-32mm

Welding form: Butt joint

Adopting the new rack-type copper sleeve design, you only need to

adjust the position of the tungsten needle, and the copper sleeve can be

directly inserted into the pipe, simplifying the welder's operation

difficulty.

Suitable for pipe extension, pipe leveling, self-melting, wire filling and other welding.

The overall structure is compact, with built-in water and electricity transmission, and 360 degrees without duct winding.

Built-in

wire feeder, lkG wire tray can be installed, water circulation cooling,

high temporary load rate of equipment: tight assembly process ensures

stable operation of the equipment.

Optimized ergonomic design, easy to use, safe and reliable

KEPUNI's orbital welding system pairs intelligent controls (expert database, weld simulation, parameter logging) with vers...

The KEPUNI TB-35 orbital welding head uses a pneumatic core expansion for self-centering clamping on thin-walled tubes (≤2...

Leverage an expert database for reliable, perfect welds. The KEPUNI TB-65 auto welding head features parameter printing &a...

Achieve rapid, high-quality tube-sheet welds. The TBS-65's unique design enables quick setup and stable operation with bui...

The KEPUNI TBM-65 automatic welding head uses a pneumatic core expansion system to self-center and firmly clamp in pipes (...