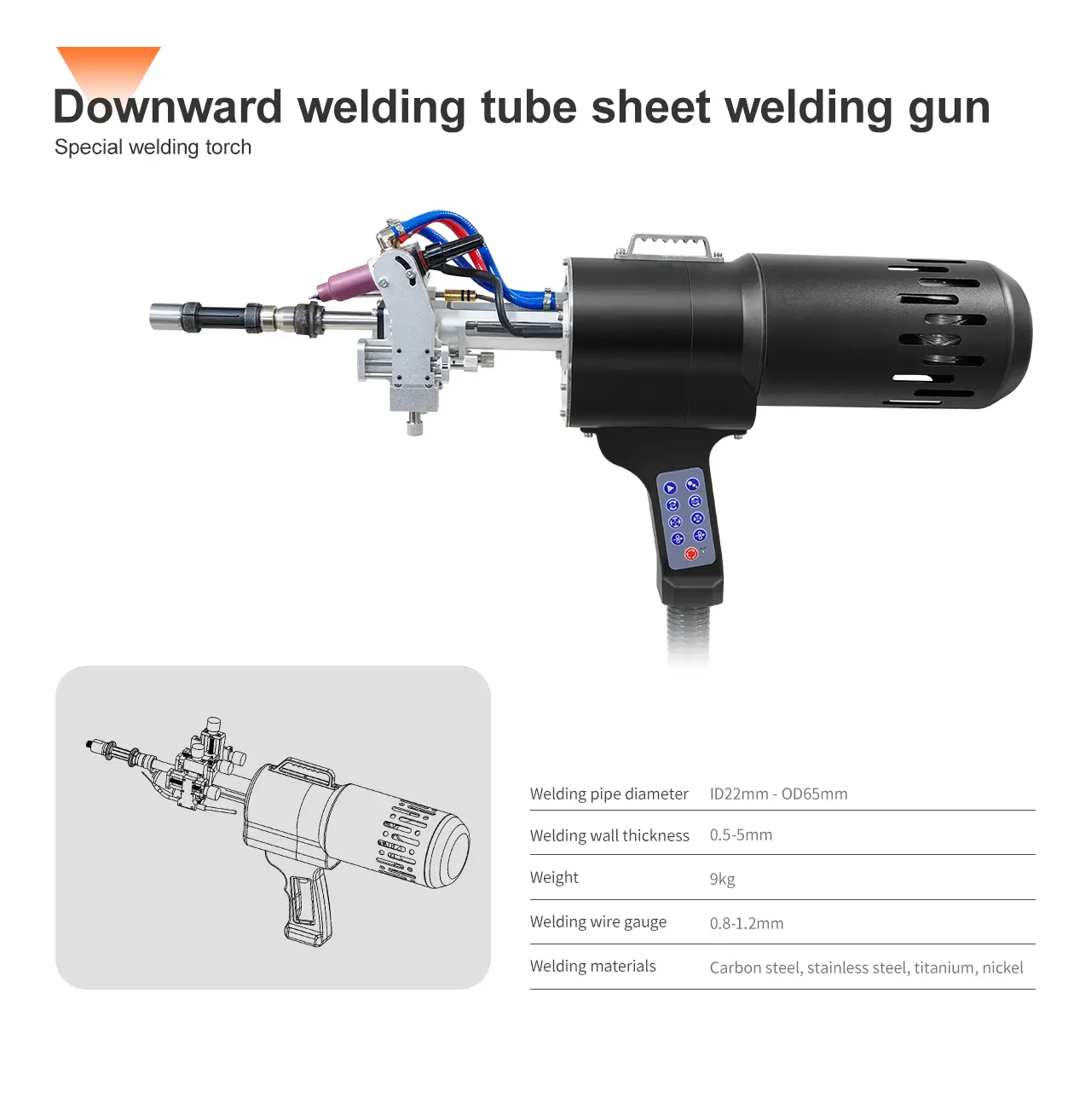

The TBM-65 welding head is a special welding head designed and developed for all-position automatic welding of various tube-to-sheet connections. The pneumatic core expansion method is adopted to fix the welding gun in the center of the pipe fitting, firmly clamp it, and simplify the difficulty of welding operation.

Welding material: Carbon steel, stainless steel, titanium, nickel, etc.

Welding wall thickness: ≤5mm

Welding head adjustment angle: 0°-60°

Welding pipe diameter:22mm-65mm

Adopting pneumatic core expansion method, the welding gun can be fixed at the center of the pipe fitting, firmly clamped, and simplifying the difficulty of welding operations

Suitable for welding pipe extension 5-10mm, pipe leveling, self melting, and wire filling

The overall structural design is compact, with internal transmission for water and electricity, and no conduit winding at 360 °

Cooling water circulation, high equipment temporary load rate; Tight assembly process ensures stable operation of equipment

Optimized ergonomic design, easy to use, safe and reliable

The KEPUNI TBM-65 is a precision-engineered welding head optimized for all-position automatic orbital welding of tube-to-tube sheet joints, offering enhanced accuracy and operational efficiency in industrial applications.

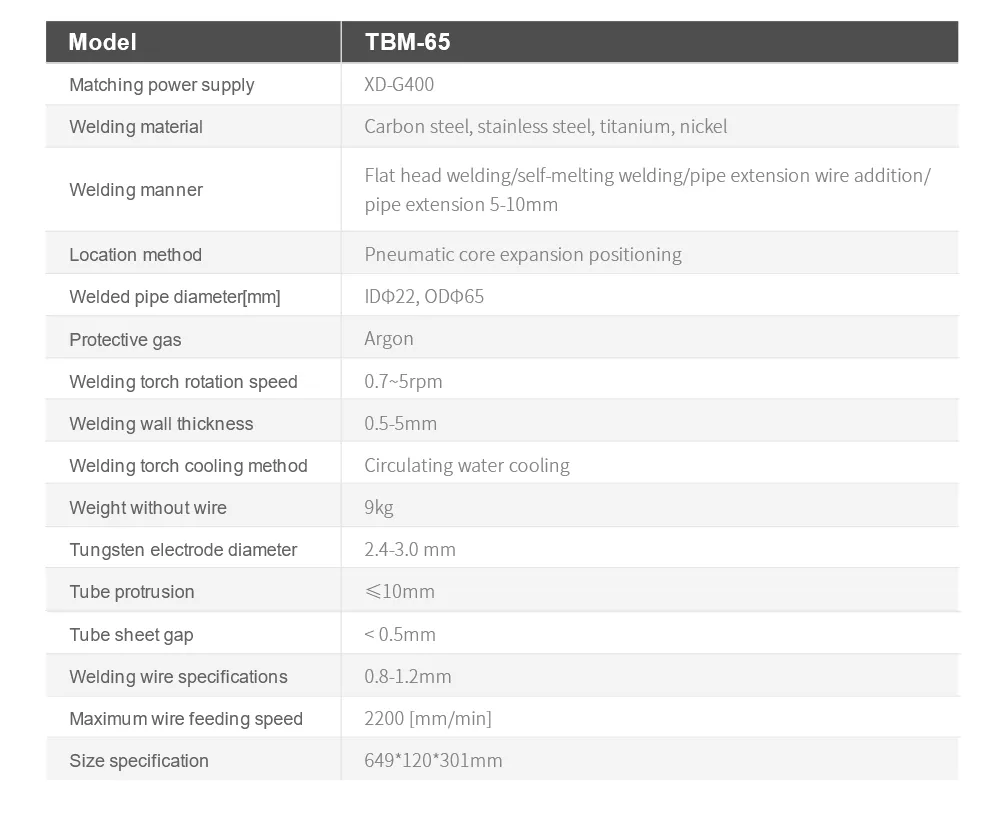

Key Specifications:

Welding wall thickness: 0.5-5mm

Welding head adjustment angle: 0°-60°

Welding pipe diameter:22mm-65mm

Welding head cooling method: Circulating water cooling

Advanced Features:

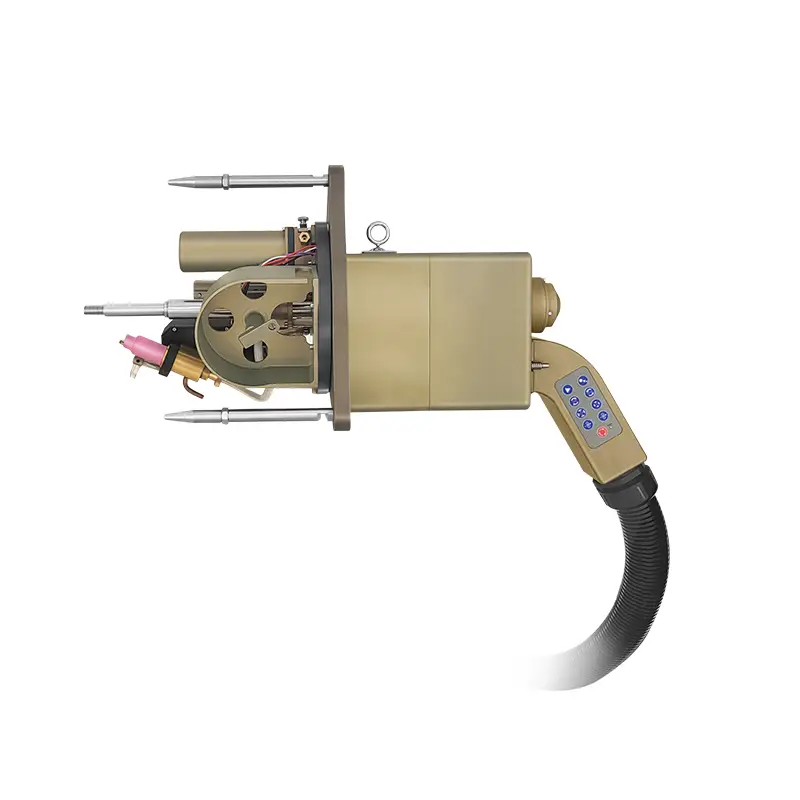

Cylinder mid-mounted technology

Compared

with the traditional rear-mounted cylinder, the center-mounted cylinder

can make better use of space and provide support for coaxial wire

feeding.

Coaxial wire feeding integrated technology

Place

the wire reel at the back so that the wire has enough space in the gun

to be straightened, and the wire comes out without bending or warping,

with good stability.

Adjustable modules

Utilizing

five slide rails and a 60° turning device, the welding torch and wire

feed port can be moved relative to each other and as a whole, and the

inclination angle of the welding torch can be adjusted.

Narrow pitch welding

The design of adjustable three-dimensional modules can minimize the pipe bridge spacing to 6mm when welding dense pipe arrays.

Applications:

Power Generation: Welds boiler tubes, heat exchangers, and steam condensers.

Petrochemical: Repairs process piping and reactor vessels.

HVAC: Fabricates chiller coils and condenser tube joints.

By

integrating automation, precision controls, and operator-centric

design, while meeting ASME Section IX and ISO 15614-1 standards.

KEPUNI's orbital welding system pairs intelligent controls (expert database, weld simulation, parameter logging) with vers...

Achieve rapid, high-quality tube-sheet welds. The TBS-65's unique design enables quick setup and stable operation with bui...

The KEPUNI TB-35 orbital welding head uses a pneumatic core expansion for self-centering clamping on thin-walled tubes (≤2...

The KEPUNI TBM-65 automatic welding head uses a pneumatic core expansion system to self-center and firmly clamp in pipes (...

Leverage an expert database for reliable, perfect welds. The KEPUNI TB-65 auto welding head features parameter printing &a...